Infrastructure is one of the key drivers of qualitative as well as quantitative manufacturing. It is the pivotal element in building a powerful, robust and technologically superlative process of manufacturing the products.

Keeping this in mind, Bhilosa has built two huge plants with state-of-the-art facilities at Rakholi and Naroli in Silvassa powered by modern technology, equipment and systems. It has automated packing lines for finished product which ensure uniform textured yarn packing, automated material movement and machines equipped with air jets from world leaders for making specialised ROTO yarn in fine and coarse denier.

A painstakingly built R & D division works diligently at bettering processes and upgrades in spinning and texturising. The company has latest Quality Management System that ensures that quality remains the cornerstone of all Bhilosa products. Taking our mission further, our state-of-the-art infrastructure only ensures that we become a process driven organisation very soon.

Some details of our machineries are as follows:

| Draw Texturised Yarn (DTY) | ||

|---|---|---|

| Capacity: | Product Range: | Machinery: |

| 638750 Metric Tons Per Annum |

50 - 1000 Denier

Semi Dull/ Full Dull/ Dope Dyed/ Bright/ Crimp/ Melange/ Fancy Yarn |

Aalidhra |

| Fully Drawn Yarn (FDY) | ||

| Capacity: | Product Range: | Machinery: |

| 328500 Metric Tons Per Annum |

30 - 1000 Denier Semi Dull/ Full Dull/ Dope Dyed/ Bright/ Cationic |

Barmag, TMT, Chonglee |

| Air Textured Yarn (ATY) | ||

| Capacity: | Product Range: | Machinery: |

| 6000 Metric Tons Per Annum |

110 - 1000 Denier Slub/ Neps/ Long Slub/ Uneven Slub/ Dope Dyed |

AIKI/ Aalidhra |

| Partially Oriented Yarn (POY) | ||

| Capacity: | Product Range: | Machinery: |

| 620500 Metric Tons Per Annum |

50 - 1000 Denier Semi Dull/ Full Dull/ Dope Dyed/ Bright |

Barmag, TMT, Chonglee |

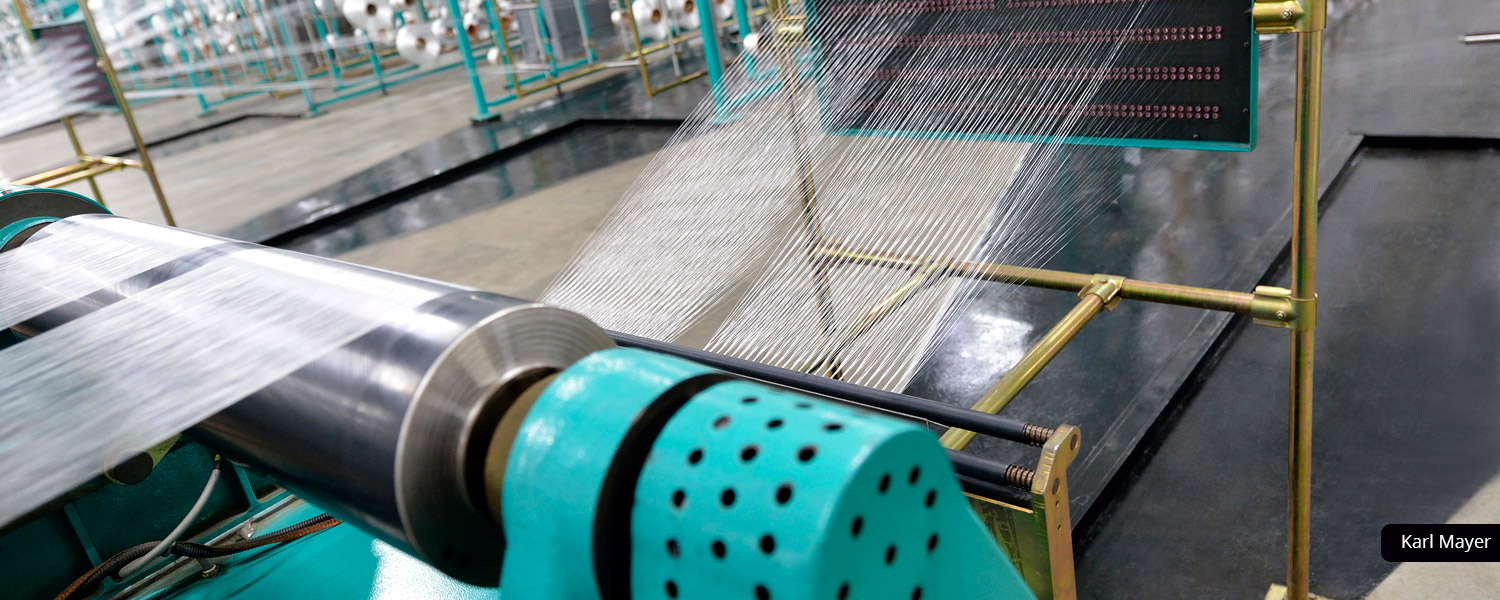

| Warp Knitted Greige Fabric | ||

| Capacity: | Product Range: | Machinery: |

| 27000 Metric Tons Per Annum |

Knitted Fabric upto 218 inches & Pile Fabric upto 182 inches |

Karl Mayer |

| Circular Knitted Fabric | ||

| Capacity: | Product Range: | Machinery: |

| 18000 Metric Tons Per Annum |

70 - 100 Denier | Mayer & CIE |

| Master Batch | ||

| Capacity: | Product Range: | Machinery: |

| 4320 Metric Tons Per Annum | Jet Black , Bluish Black, grayish black | Coperion , K-tron |

| Polyester Staple Fibre | ||

| Capacity: | Product Range: | Machinery: |

| 162000 Metric Tons Per Annum |

0.8, 1.0, 1.2, 1.4 Denier Semi Dull 1.2, 1.4 Denier OPW 1.2 Denier SHT 1.2, 1.4 Denier BDD 1.4/ 2.0 D TRILOBAL These products will be available in all required staple lengths |

Neumag |

Manufacturing Unit – Naroli

Manufacturing Unit – Rakholi

The essence of fine workmanship finds its roots in the level of quality control methods practised by the company. After all a good quality product gives you an edge above the rest. Bhilosa has earned many important certifications that bear a hallmark of assurance of quality. Some of them are:

- An ISO 9001:2015 & ISO 45001:2018 Certified company

- An Oeko-Tex Association Certificate that ensures all products are made with material tested for harmful substances, in environmentally friendly facilities and in safe and socially responsible work places.

- Online Tension Monitoring System (OLT) which is complete solution for online quality assurance and integrated doff timer for equal length packages. Improved market reputation and competitiveness by producing consistent quality & equal length packages.

- Worlds best inspection and testing instruments that form a part of Quality Control Department.

- Automatic Tensile testers (Statimat ME+ of Textechno, Germany)

- Texturmat for Crimp & Bulk characteristics (M/s Textechno, Germany)

- Draw force / tension tester (DTI-600 of M/s Lenzing, Austria and Dynafil-ME+ of Textechno, Germany)

- Spin Finish Analyser NMR (ALFA of Lenzing, Austria)

- Evenness Tester (M/s Keisokki, Japan)

- DSC (M/s Perkin Elmer, USA)

- Automatic Viscosity Analyser (M/s Schott, Germany)

- Gas Chromatograph (M/s Shimadzu, Japan)

- U. V. Spectrophotometer (M/s Shimadzu, Japan)

- Colour Analysis (M/s Hunter, USA)

- Karl Fischer titrator (M/s Metrohm, Switzerland)

- Rapid – 600 (Lenzing Make) for number of NIPS / NIPS strength of Yarn

- Texturmat (Textechno) for shrinkage / bulk properties of Yarn

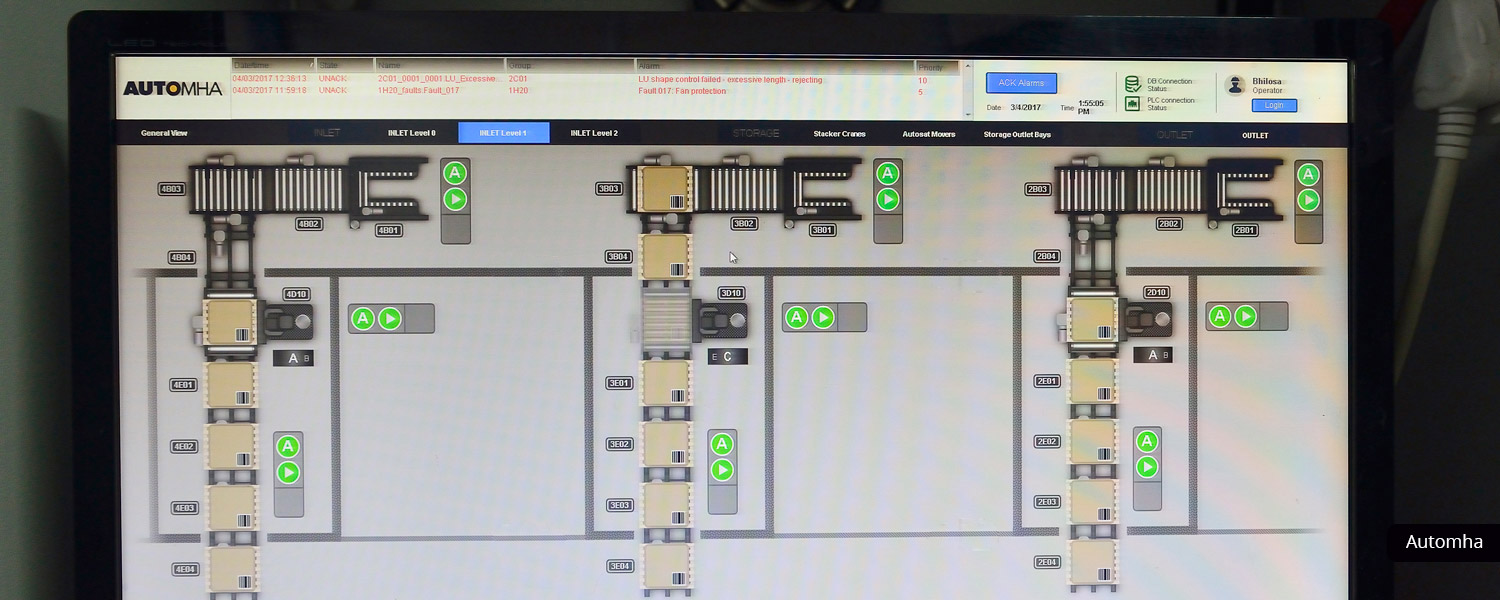

At Bhilosa, ‘technology is a way of life’ since it is always for the betterment of our systems. Hence a greater part of effort is being put towards technology that avoid human error. Our latest automated warehousing facility is a unique system wherein, the processing speed of packing the contents in the box to delivering the final packed output happens literally at the speed of thought. Due to less human interference in the process, the swiftness, speed and accuracy is extremely commendable.

It is not surprising that this system is one-of-its-kind in the Industry. Its massiveness, quality and technology is what makes it professionally impeccable.

The acceptance of such ideas pertaining to newer technology, has helped us improve, in our quest to become one of the leading Polyster Yarn companies across the globe.